Disclaimer:

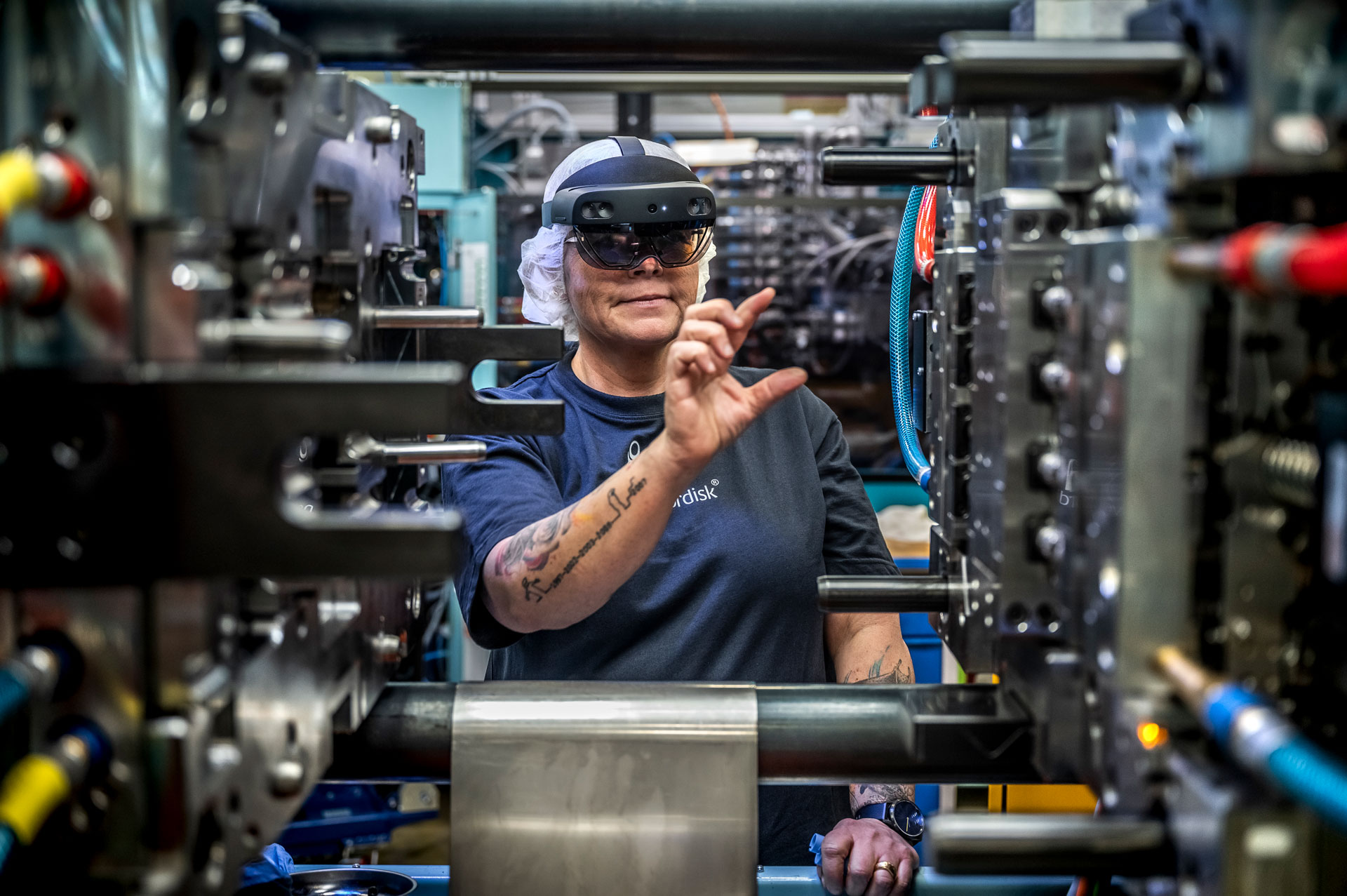

The video and images are from the Microsoft article Microsoft Customer Story-Novo Nordisk uses mixed reality to improve processes in a GxP environment

As part of Novo Nordisk’s digital strategy, we are adopting new digital technology to help drive growth and reach more patients. We want to optimise the way we work and one of the ways we are leveraging this ambition is by using Mixed Reality. Mixed Reality helps us improve process performance at many of our manufacturing facilities and by introducing this technology we experience an increase in efficiency, a more flexible workforce, and faster training of new employees.

Mixed Reality blends the real world with the virtual world. When you put on a HoloLens2, you can move around and operate in the physical world but with a virtual layer on top. The Augmented Instructions will guide you through the process you are about to perform. This is particularly useful for employees performing complex tasks on production lines or for training purposes. Instead of reading a traditional 2D instruction, the employee can put on the device and get an “augmented” instruction - with 3D animations in the surroundings of the actual equipment at a production line.

The Augmented Instruction is a solution that uses the Microsoft HoloLens 2 and Microsoft Dynamics 365 applications to digitally support manual processes. The final part of the solution involves a Power Platform and a Power Automate-driven platform that run in the backend and helps to configure and automate processes, trigger workflows, and manage processes. This allows us to apply Augmented Instructions in compliance with the strict requirements imposed on the pharmaceutical industry.

We have big aspirations for the future and believe that there are several advantages to implementing this technology. Widespread use of Augmented Instructions will lead to an increase in production performance. It will also make our employees more agile by enabling on-the-job assistance when needed. In addition, employees can call a specialist for help through the actual device. We expect this technology to speed up the onboarding of new employees and provide employees opportunities to take on more and more complex tasks. This enables a more engaging and rewarding work for our manufacturing employees driving change for people living with diabetes and other serious chronic diseases every single day.

Widespread use of Augmented Instructions will lead to an increase in production performance. It will also make our employees more agile, enabling on-the-job assistance when needed.